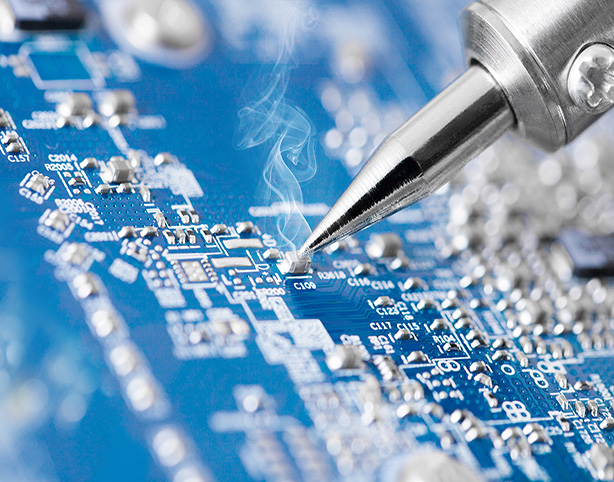

MELSiS – Mikro Elektronik Sistemler Ltd. Şti. Tam otomatik dizgi hattı ile elektronik kart üretimi ve SMD dizgi hizmeti sunmaktadır.

SMD dizgilerimiz; ESD kontrollü alanda, IPC-A-610 & IPC J-STD-001 eğitimleri alan personelimiz ile IPC-A-610 & IPC J-STD-001 standartlarına uygun olarak dizgi atölyemizde gerçekleştirilmektedir. Seri ve prototip üretimde tek veya çift yüzlü elektronik kartları siz değerli müşterilerimize hızlı ve kaliteli bir şekilde sunabilmekteyiz. SAMSUNG SM482 SMD makinamız ve full otomatik hattımız günde 350.000 malzeme, dip dizgide günlük 5000 malzeme dizme kapasitesine sahiptir. SMD dizgide müşteri talebine göre kurşunlu ya da kurşunsuz olarak lehimleme işlemi gerçekleştirilmektedir.